The Ultimate Guide to Starting Your Custom Bag Project: From Tech Pack to Sample

In the bag and luggage industry, every great product starts with an idea. But for many emerging brands, corporate buyers, or designers, the most challenging part is often not the design itself, but how to transform a paper sketch into a mass-producible physical product.

As a professional bag manufacturing partner, BagmakerPro understands the critical nature of this process. Whether you are developing an outdoor backpack, a fashionable women’s bag, a business laptop bag, a men’s bag, or a durable student bag, the journey from the Tech Pack to the Pre-production Sample (PPS) determines your product’s success.

This guide will walk you through our efficient custom manufacturing (OEM/ODM) process, helping you navigate common pitfalls and accelerate your project timeline.

Step One: Idea Formulation and the Tech Pack

Everything begins with clear communication. To ensure the factory accurately understands your vision, we must translate abstract ideas into concrete engineering language. This is the function of the Tech Pack—the blueprint for your product.

What Makes an Effective Tech Pack? More than just a sketch, a standard Tech Pack should include:

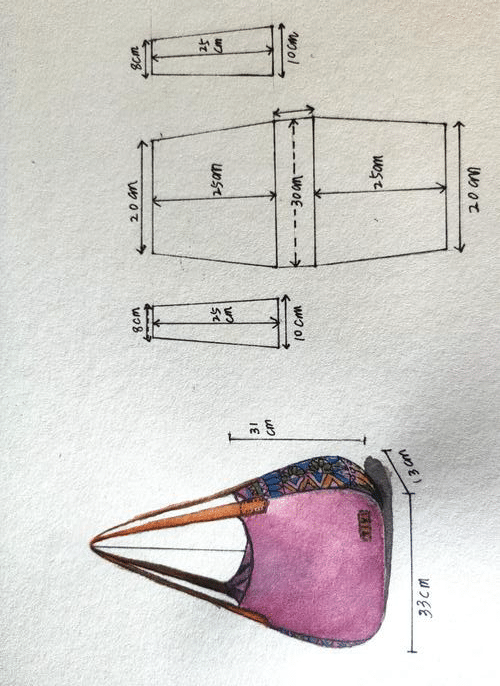

- Design Drawings (Sketches): Detailed views of the front, back, side, and internal structures.

- Measurement Specifications: Precise dimensions (length, width, height) and specific pocket/strap sizes.

- Bill of Materials (BOM): Specified primary fabrics (e.g., 500D Cordura, Canvas, PU leather), lining, zipper brands (e.g., YKK, SBS), buckles, and webbing specifications.

- Color & Logo Treatment: Pantone color codes, and details on whether the Logo is embroidered, silk-screened, or a rubber patch.

💡 Expert Tip: If you do not have a professional Tech Pack, don’t worry. Our design and engineering team can assist you in finalizing these details based on your reference images or hand-drawn sketches.

Step Two: Cost Estimation and Swift Sourcing (Quotation & Sourcing)

Upon receiving your design requirements, we move into the evaluation stage. This step is not just about quoting; it’s about finding the optimal cost-performance solution for you.

- Industrial Zone Advantage: Leveraging the robust supply chain of the Baigou Industrial Zone in Hebei, we can quickly source the materials and accessories that meet your requirements, ensuring competitive pricing and quality.

- Process Evaluation: Our engineering team analyzes the design for mass production feasibility and offers constructive suggestions to potentially lower costs or enhance durability.

- Initial Quotation: We provide a quote that includes the Sample Fee and the estimated unit price for bulk orders.

Step Three: Sample Making—The Moment of Transformation (Prototyping)

This is the most exciting phase: transforming the two-dimensional blueprint into a three-dimensional reality.

- Pattern Making: Our experienced pattern masters use CAD systems or manual drawing to create precise patterns, ensuring every single cut piece is accurate.

- Rapid Sampling Cycle: With efficient sample room management, we commit to completing the first prototype (First Sample) within 5-10 days of receiving finalized specifications.

- First Prototype Completion: At this stage, you will receive the first tangible sample for immediate review.

Step Four: Feedback, Approval, and Low MOQ Support (Feedback & Golden Sample)

It is rare for a sample to be perfect the first time, which is why the sampling process is essential.

Upon receiving the sample, you need to check:

- Are the dimensions correct?

- Is the carrying system comfortable?

- Is the pocket layout logical?

- Are the material color and hand-feel accurate?

We will make adjustments based on your feedback. Once the sample fully meets your standards, it becomes the Golden Sample—the definitive benchmark for your order.

- Flexible MOQ Support: We are committed to supporting your business growth. For custom projects (OEM/ODM), we support a low Minimum Order Quantity (MOQ) of 200 units. We also offer 20 units MOQ for ready-stock items.

Step Five: Preparation for Mass Production and Quality Control (Ready for Mass Production & QC)

Once you have signed off on and confirmed the Golden Sample, we are ready to move into the bulk production phase.

- Production Launch: All subsequent work orders and material purchasing will strictly adhere to the standards of your approved Golden Sample.

- Rigorous Quality Control: We have comprehensive QC procedures, ensuring every bag that leaves our factory meets high quality standards and complies with international trade requirements.

Why Choose BagmakerPro as Your Custom Bag Partner?

- Baigou Industrial Advantage: Leveraging the supply chain of the “Capital of Bags,” we ensure high-value materials and mature production techniques.

- Fast Sampling Commitment: Prototypes are ready in just 5-10 days, allowing you to verify your design quickly and seize market opportunities.

- Flexible Support: We support a low custom MOQ of 200 units, perfect for emerging brands and small batch testing.

- Full Product Line: Specializing in the production of a complete range of bags, including Outdoor, Women’s, Men’s, Laptop, and Student Bags.

Ready to start your bag project? Don’t let a great design stay on paper. Contact our expert team today, upload your Tech Pack or design ideas, and let us provide you with a complimentary project consultation!