In the global luggage and bag industry, the phrase “Made in China” has evolved. Today, at BagMakerPro, it stands for precision, advanced engineering, and, above all, uncompromising Quality Control (QC).

For international buyers, the primary risk isn’t just a defective product; it’s the damage to their brand reputation and the high cost of returns. To mitigate this, we have implemented a Standardized 4-Stage QC Ecosystem that ensures every bag leaving our facility is a masterpiece of durability.

Here is an in-depth look at how we protect your brand at every stage of production.

Stage 1: Incoming Quality Control (IQC) – The Foundation

A bag is only as strong as its weakest component. Our QC process begins long before the sewing machines start humming.

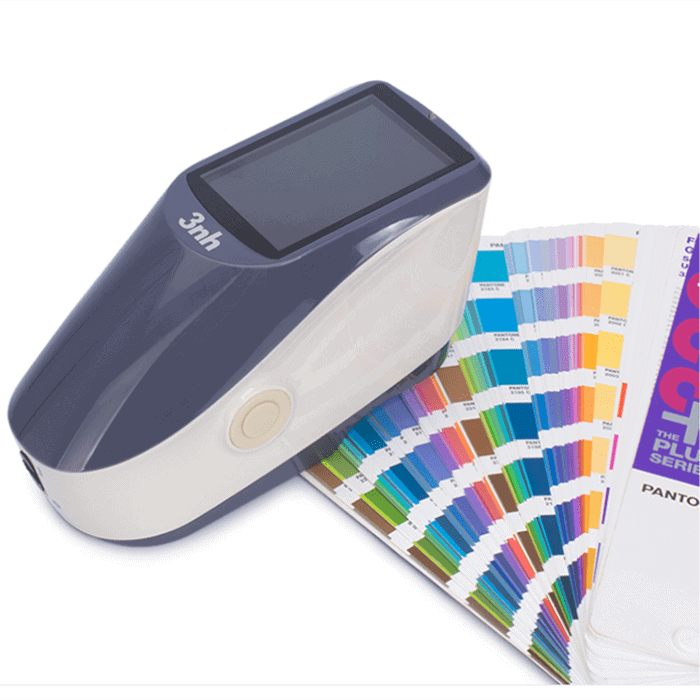

- Fabric Color Consistency (Lab Testing): We use Spectrophotometers to ensure that the fabric color matches your Pantone requirement within a delta-E tolerance of < 1.0. This prevents “color shading” issues across different production batches.

- Tensile Strength & Abrasion Resistance: We don’t just feel the fabric; we test it. Our lab checks the Denier count and performs Martindale abrasion tests to ensure the material won’t pilling or tear under daily wear.

- SGS-Verified Hardware: We inspect zippers (YKK or high-quality local brands), buckles, and D-rings. Our “Salt Spray Chamber” simulates years of exposure to salty sea air to ensure no oxidation or rusting occurs on metal parts.

Stage 2: During Production (DUPRO) – Precision in Motion

Once production starts, our “In-Line” inspectors act as the eyes and ears of our clients. We follow a “First Piece Approval” protocol.

- The “Golden Sample” Calibration: Before the full line starts, the line leader and QC manager sign off on the first finished unit. This becomes the benchmark for the entire run.

- SPI (Stitches Per Inch) Calibration: For high-end backpacks, we maintain a strict 7–9 stitches per inch to ensure maximum seam strength and a premium aesthetic.

- Internal Binding & Finishing: We check the “guts” of the bag. Our inspectors ensure that all internal seams are properly bound with bias tape, leaving no raw edges that could fray over time.

Stage 3: Functional Stress Testing – Simulating Real-World Use

At BagMakerPro, we believe in “destructive testing” to guarantee constructive results. We put random samples from the production line through a series of grueling tests:

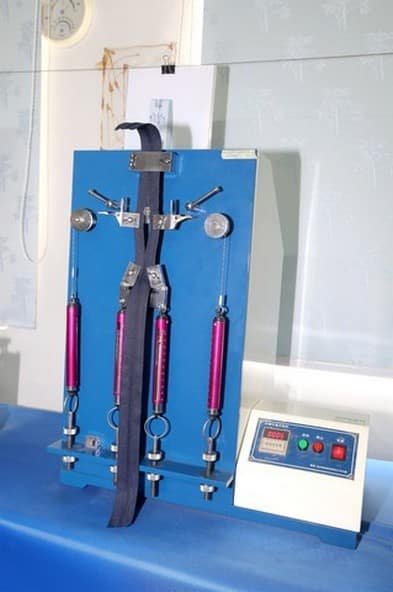

- The Static & Dynamic Load Test: We load a laptop bag with 15kg of weight and subject it to a Jerk Test (a machine that drops the bag repeatedly by the handle). If a strap so much as creaks, the batch is halted for reinforcement.

- Zipper Cycle Endurance: Using an automated reciprocating tester, we pull zippers 5,000 times. They must remain as smooth on the 5,000th pull as they were on the first.

- Water Repellency (AATCC Standards): For outdoor and tech bags, we perform “Spray Tests” to verify that the DWR (Durable Water Repellent) coating meets international standards.

Stage 4: Final Random Inspection (FRI) & Needle Detection

Before the bags are boxed, they undergo a final, exhaustive audit following the ISO 2859-1 (AQL 2.5 / 4.0) standard.

- The X-Ray Needle Detector: This is a non-negotiable step. Every single bag passes through a conveyor-belt metal detector to ensure no broken sewing needles or metal fragments are trapped inside—a critical safety requirement for the EU and US markets.

- Aesthetic Final Polish: We use industrial heat guns to trim loose threads and steam cleaners to remove any packing creases, ensuring the bag looks “retail-ready” the moment it’s unpacked.

- Packaging Integrity: We verify carton burst strength (ECT) to ensure your goods won’t be crushed during ocean freight or rough handling at the destination port.

Why Transparency is Our Best Policy

We understand that you can’t always be on the factory floor. That’s why we provide:

- Digital QC Reports: Detailed PDF reports with high-resolution photos of every test performed.

- Live Video Audits: We offer scheduled “Virtual Factory Tours” via Zoom or WhatsApp, allowing you to see your production line in real-time.

- Third-Party Integration: We fully welcome external inspectors (SGS, Intertek, V-Trust) and provide them with a dedicated workspace and full cooperation.

Conclusion: Partner with a Factory That Cares as Much as You Do

Quality control is not an expense; it is an investment in your brand’s future. By choosing BagMakerPro, you are choosing a partner dedicated to the “Zero-Defect” philosophy.

Ready to elevate your product quality? [Request our Full QC Manual] | [Get a Quote for Your Next Project] | [Book a Factory Tour]