Importing children’s products is a high-stakes game.

When you import adult backpacks, a broken zipper is a quality issue—it might cost you a refund. But when you import children’s school bags, a zipper puller containing high lead levels is a legal issue.

It can lead to customs seizures, massive fines, and the nightmare of a Product Recall that destroys your brand reputation on Amazon or in local retail chains.

At BagMakerPro, located in the heart of Baigou’s manufacturing hub, we operate with a simple philosophy: Safety First. We don’t just stitch bags; we engineer compliant products that protect your business and the children who use them.

Here is your essential safety checklist for sourcing kids’ backpacks for the US and European markets.

1.The “Big Two” Chemical Regulations: What You Must Know

Chemical compliance is invisible to the naked eye, but it is the most common reason for border rejections.

USA: CPSIA Compliance

For the US market, the Consumer Product Safety Improvement Act (CPSIA) is non-negotiable for products intended for children under 12.

- Lead (Pb) Content: All accessible components—zippers, buttons, and especially the ink used for edge painting—must contain less than 100 ppm of lead.

- Phthalates: Often used to soften plastics, strict limits apply to specific phthalates in children’s toys and care articles.

How BagMakerPro Ensures This: We pre-test our raw materials. Our zipper suppliers provide test reports proving their metal and coating are lead-free.

Europe: REACH & SVHC

For the EU market, the REACH regulation applies.

- SVHC (Substances of Very High Concern): Importers must know if their products contain any SVHCs above 0.1% by weight.

- OEKO-TEX Standard: To ensure peace of mind, we source fabrics from suppliers who hold OEKO-TEX certifications, guaranteeing the textiles are free from harmful substances like azo dyes and formaldehyde.

Pro Tip for Buyers: Always ask your factory: “Do you have recent test reports for your edge paint and PVC materials?”

2.Physical Safety Checklist: The Factory Floor Reality

Chemicals aren’t the only risk. Physical hazards can cause injury. Here is how we inspect every school bag before it leaves our factory.

Choking Hazards (Small Parts)

For bags targeting younger children (Pre-K to Kindergarten), small parts are a major risk.

- The Puller Test: Decorative rubber pullers or cute charms must be securely attached. We perform tension tests to ensure they cannot be easily ripped off and swallowed by a child.

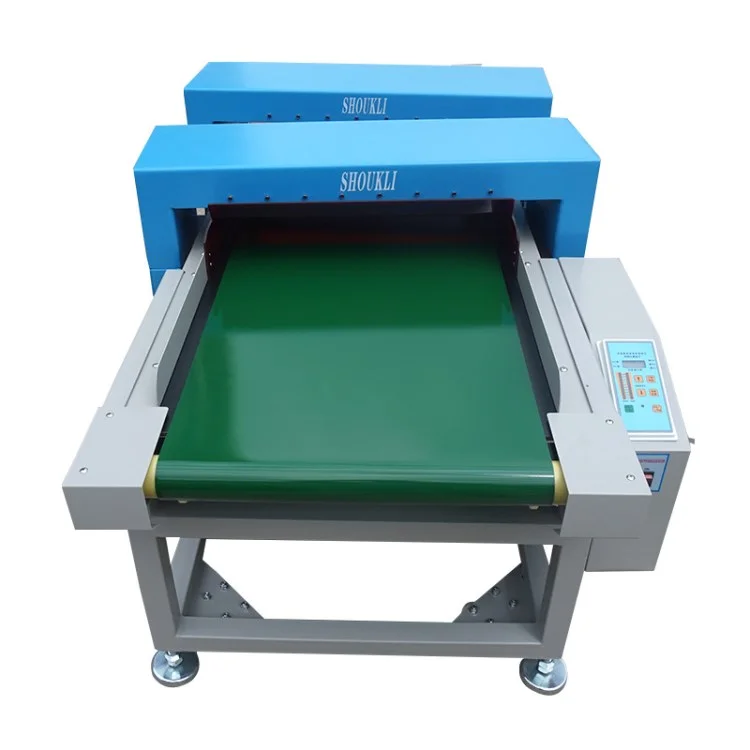

Needle Detection: Zero Tolerance

This is the most critical step in our packing line. A broken sewing needle fragment left inside a backpack is a disaster waiting to happen.

- Our Process: Every single bag passes through a calibrated Needle Detector Machine. If the machine beeps, the bag is isolated and re-inspected until the metal fragment is found and removed. We have a zero-tolerance policy for metal contamination.

Visibility Safety (Reflective Strips)

Safety includes the child’s journey to school.

EN13356 Standard: We incorporate high-visibility reflective strips on the front pocket and shoulder straps. These reflect car headlights in low-light conditions (rain or winter evenings), keeping students safe on the road.

3.Ergonomics: Protecting Growing Spines

Buyers often focus on the print design, but parents (and school procurement officers) focus on health. A heavy, poorly designed bag can impact a child’s posture.

- S-Curve Straps: We cut our shoulder straps in an “S” shape, not a straight line. This contours to a child’s body, distributing weight evenly across the shoulders rather than digging into the neck.

- Breathable Mesh Backing: Children run and sweat. We use multi-layer 3D air mesh on the back panel to allow airflow, preventing heat buildup and providing a cushion against heavy textbooks.

Conclusion: Don’t Risk Your Business on Non-Compliant Bags

Sourcing cheap is easy. Sourcing safe is a skill.

As an Amazon seller or retailer, you cannot afford to worry about whether your container will clear customs or if your product will be flagged for chemical violations. You need a manufacturing partner who acts as your compliance guardian.

Ready to upgrade your supply chain?

Contact BagMakerPro today for a safe, fully certified school bag sample. Let’s build a product that parents trust and kids love.