In the world of bag manufacturing and sourcing, few specs are as commonly cited—and as commonly misunderstood—as the Denier (D) rating.

Whether you are sourcing tactical backpacks, fashion totes, or travel luggage, you will see terms like “600D,” “1000D,” or “Ballistic Nylon” thrown around in every quotation. But does a higher number always mean a better bag? Not necessarily.

For procurement officers and boutique owners, choosing the wrong fabric density can lead to two problems: overpaying for unnecessary durability or facing returns due to flimsy materials.

As a factory specializing in bag production, we’ve created this guide to help you navigate the balance between Durability and Cost.

What Exactly is “Denier”?

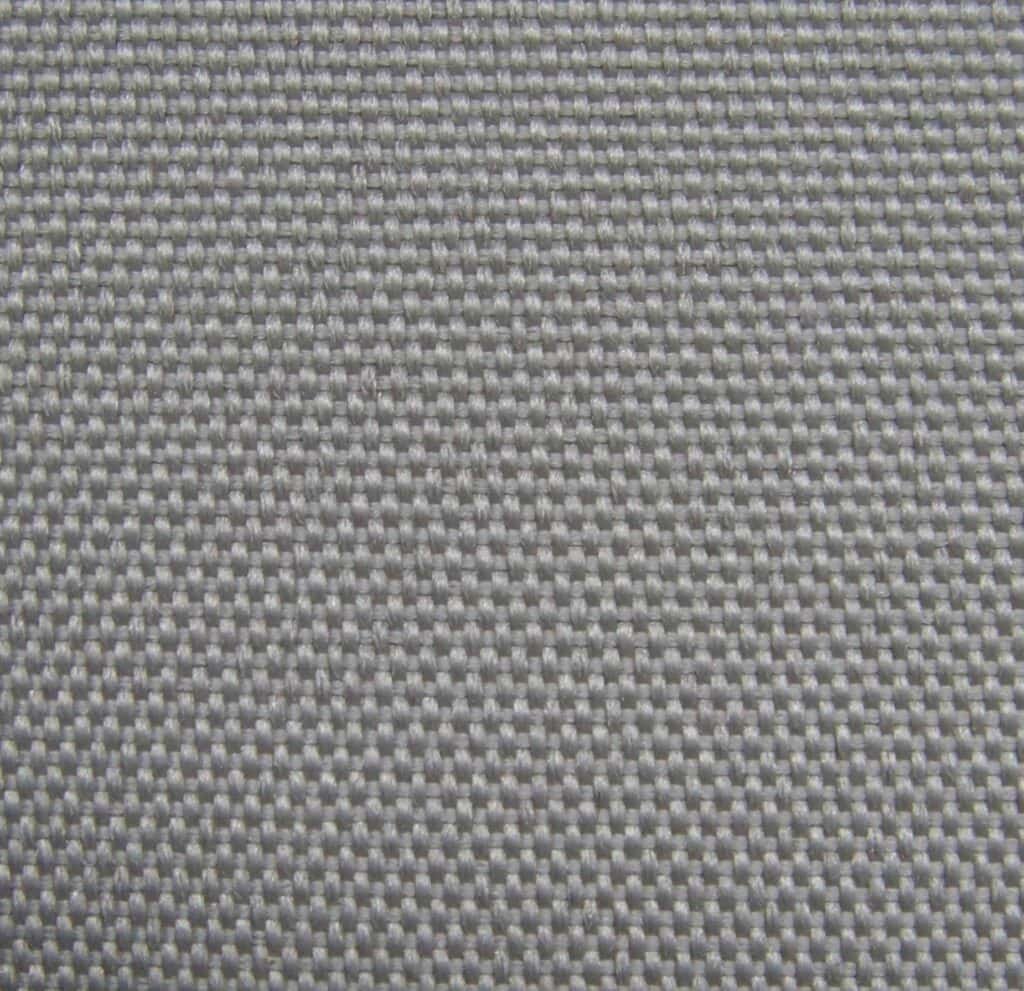

In technical terms, Denier (D) is a unit of measure for the linear mass density of fibers. Specifically, it is the mass in grams of 9,000 meters of the fiber.

- In simple terms: It measures the thickness and weight of the thread used to weave the fabric.

- The Rule of Thumb: generally, the higher the Denier count, the thicker, heavier, and more durable the fabric is.

- The Exception: Material matters. A 420D High-Quality Nylon is often stronger than a 600D cheap Polyester.

Common Deniers You Will Encounter in Our Catalog

When browsing our [Backpack Collection] or [Duffel Bag/Travel Bag], you will typically see these three industry standards:

1.The Economy Standard: 600D Polyester

This is the workhorse of the bag industry. It is used in about 70% of school bags, promotional totes, and basic backpacks.

- Pros: Very affordable, holds color well, sufficient for daily use.

- Cons: Not waterproof without coating, less abrasion-resistant than nylon.

- Best For: Promotional gifts, school backpacks, basic cosmetic bags.

2.The Performance Choice: 420D / 500D Nylon

Don’t let the lower number fool you. Nylon is inherently stronger than polyester. 500D Nylon (often branded as Cordura® in high-end markets) offers an incredible strength-to-weight ratio.

- Pros: Lightweight, high tear resistance, water-resistant.

- Cons: More expensive than 600D Polyester.

- Best For: Hiking backpacks, foldable travel bags, premium toiletry bags.

3.The Heavy-Duty King: 1050D / 1680D “Ballistic”

Originally developed for flak jackets, “Ballistic” weaves are thick, tough, and heavy.

- Pros: Virtually indestructible, premium “rough” texture, high perceived value.

- Cons: Heavy, stiff, and higher cost.

- Best For: Check-in luggage, tool bags, tactical gear, laptop briefcases.

The Procurement Checklist: How to Choose?

Before you finalize your order with us, use this checklist to ensure you are selecting the right Denier for your target market.

✅ 1. Define the End-Use Environment

- Daily Commute: 600D Polyester is usually sufficient and keeps the price competitive.

- Outdoor/Adventure: You must upgrade to Nylon (420D or higher) for water and tear resistance.

- Luxury/Fashion: Focus less on Denier and more on texture. Sometimes a fine 210D Twill looks more “expensive” than a rugged 1680D.

✅ 2. Check the Backing (Coating)

The Denier is only half the story. The “Backing”—the coating applied to the backside of the fabric—provides structure and waterproofing.

- PVC Backing: Makes the fabric stiff and waterproof. Great for structured backpacks.

- PU Backing: Softer and lighter. Better for fashion bags or packable items.

- Procurement Tip: Always ask us: “Is this 600D with PVC or PU backing?”

✅ 3. Weigh the “Weight”

Higher Denier means a heavier bag.

- If you are selling to primary school children, a 1680D bag might be too heavy before books are even added.

- If you are selling luggage, the extra weight of 1680D signals quality and sturdiness to the customer.

✅ 4. The Cost vs. Value Calculation

Here is a simplified comparison of how fabric choice affects FOB price (estimates only):

| Fabric Type | Durability | Weight | Relative Cost Index | Recommended Application |

| 210D Polyester | Low | Light | $ | Linings, Drawstring Bags |

| 600D Polyester | Medium | Medium | $$ | School Bags, Promo Items |

| 420D Nylon | High | Light | $$$ | Hiking Backpack, Travel Organizers |

| 1680D Ballistic | Very High | Heavy | $$$$ | Luggage, Laptop Bags |

“Note on Fashion Bags: For our fashion handbags and faux fur totes, Denier ratings apply primarily to the lining (interior fabric). A high-quality lining (like a custom branded 210D) adds a hidden touch of luxury to your vegan leather bags.”

Conclusion: Let Us Help You Source Smarter

At BagmakerPro, we don’t just sell bags; we help you engineer the perfect product for your market.

If you are aiming for a budget-friendly promotional campaign, we will recommend a crisp 600D Polyester. If you are launching a premium travel brand, we will guide you toward high-density Nylon or Ballistic fabrics.

Ready to start your next project? Stop guessing about fabrics. Contact our team today for a Free Material Swatch Book or a custom quotation.